End-to-End provision of all relevant services

in between.

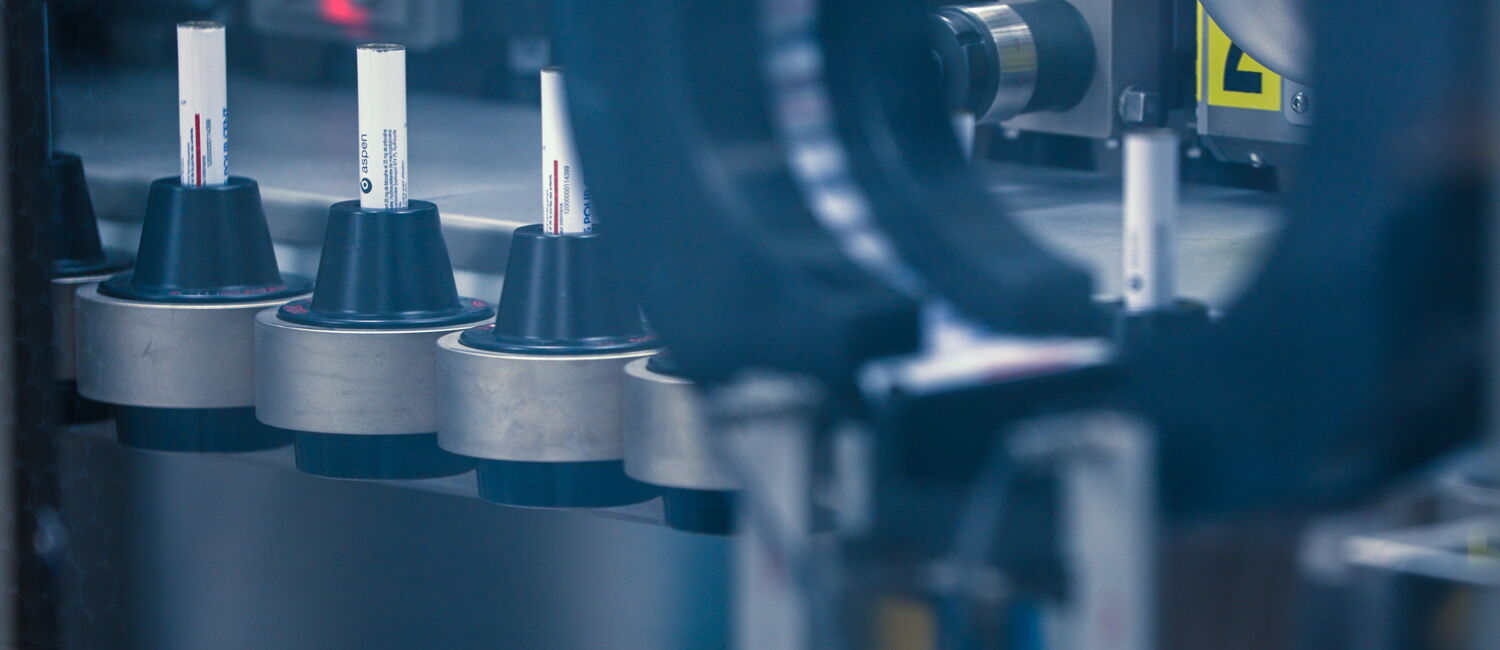

Our finished drug products are as much differentiated as our patients’ individual needs. This is why we are offering so many different dose forms:

- Tablets for ingestion

- Creams, Ointments, Gels for application on the skin or mucosa

- Solutions and suspensions for ingestion

- Solutions and suspensions for application on the skin or mucosa

- Blow-Fill-Seal-ampoules with solutions for inhalation after dilution

This very high variety of dose forms helps our patients to apply or take their medication exactly as prescribed by their medical doctor.

Be the best

you can be.

Our drug products are meant to enable patients to fight their diseases and sufferings themselves. For us as a drug product manufacturer this means: We need to focus on our technological strengths enabling us to provide the best support to our patients.

We are experts for:

- ow dosed, highly active ingredients

- Hormones

- Local anaesthetics

- Narcotics

- Antibiotics for children

- Sterile gels

- Sterile solutions in Blow-Fill-Seal-ampoules

We use our expertise so that our patients can regain their own strengths

Annual

output.

By manufacturing significant numbers of doses for all our dose forms reliably every year, we do our bit to improve the global availability of medication.

Every year, we are producing the following approximate amounts of products at Bad Oldesloe:

- 2,000,000,000 tablets

- 100,000,000 Blow-Fill-Seal-ampoules

- 8,000,000 bottles of oral liquids

- 5,000,000 bottles of topical liquids

- 3,000,000 tubes of creams, ointments and sterile gels

Because we never want our patients to go away empty-handed.

From Bad Oldesloe

into the world.

Our patients live in more than 150 countries in 6 different regions:

- Europe

- Africa

- Latin America

- Middle East

- Asia incl. Australia and New Zealand

- North America

But all of our patients are profiting from our same consistent product quality made in Germany.

Everything

in our own hands.

In order for our products to provide the maximum possible benefit to patients, it is essential for us to perform thorough chemical, microbiological and physical analysis. But because you can't make good out of something bad, we apply the same for our raw materials as well. And because we are responsible for our product quality ourselves, we prefer to have our own staff from Quality Control to analyze all finished goods as well as incoming materials themselves in-house.

Our Quality Control department is structured in the following divisions:

- Laboratory for analysis of tablet products

- Laboratory for analysis of liquid and semisolid products

- Microbiological laboratory

- Laboratory for analysis of raw materials

Because we want to ensure our products are as pure as a white lab coat before they reach our patients.

The only way to produce and analyze state-of-the-art finished dose forms at commercial scale is the use of high throughput production scale manufacturing and packaging lines as well as high performance lab equipment.

Therefore, our Engineering team offers the full service for both our production and our laboratories in terms of:

- Choosing a suitable machine design and confirming requirements with machine suppliers

- Machine service

- Plant maintenance and machine repairs

Because our production team needs to focus on output for our patients, not on stoppages.